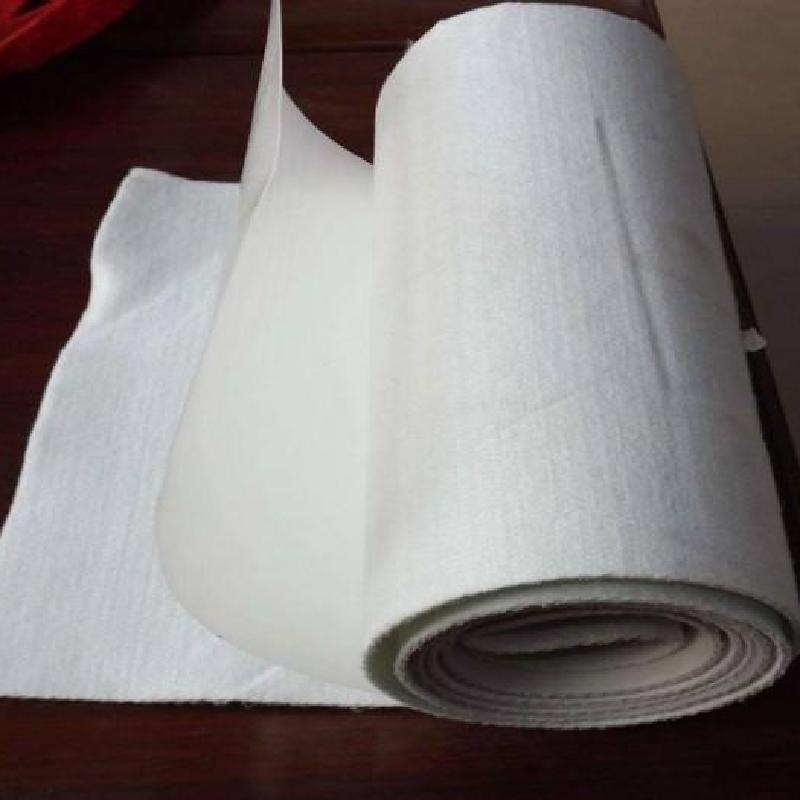

Composite Geomembrane Filament Cloth

Composite geomembrane filament cloth of filament composite geotextiles, such as tensile strength, tear resistance, and puncture resistance, are significantly higher than those of geotextiles and geomembranes. Composite geomembrane filament cloth These materials can meet the requirements of various civil engineering projects, including water conservancy, municipal works, embankments, tunnels, and culverts. Due to their high strength, resistance to aging, acid and alkali, and wear, filament composite geotextiles can also be used in non-standard environmental conditions.

Composite Geomembrane Filament Cloth is a type of composite geotextile membrane. It is a new type of geosynthetic material that combines long filament geotextiles with geotextile membranes. When the edges of the membrane are covered with short filament geotextiles, Composite geomembrane filament cloth it is called a short filament composite geotextile membrane. If the edges are covered with long filament geotextiles, it is referred to as a long filament composite geotextile membrane. Composite membranes are typically available in configurations of one fabric and one film, two fabrics and one film, or multiple fabrics and multiple films, and are primarily used for seepage prevention.

Construction Method:

1. Preparation for Laying: Before laying, the construction site must be inspected to ensure the base is flat and free of sharp objects or stones. Within the anti-seepage area, all tree roots should be removed. Construction can only proceed after passing the inspection.

2. Laying Direction: The membrane should generally be laid from bottom to top. When overlapping, reserve a 10mm-30mm overlap for welding. In colder temperatures, the edges should be tightened, but not too tightly, allowing for some expansion to prevent deformation. For large-scale laying, sandbags should be used to weigh down the edges after laying to prevent strong winds from affecting the subsequent welding of the geotextile membrane.

3. Timely Backfilling: After laying, backfill the soil promptly. Avoid walking on the backfilled soil with thick-soled or spiked shoes until the backfill is complete to prevent accidental damage to the membrane.