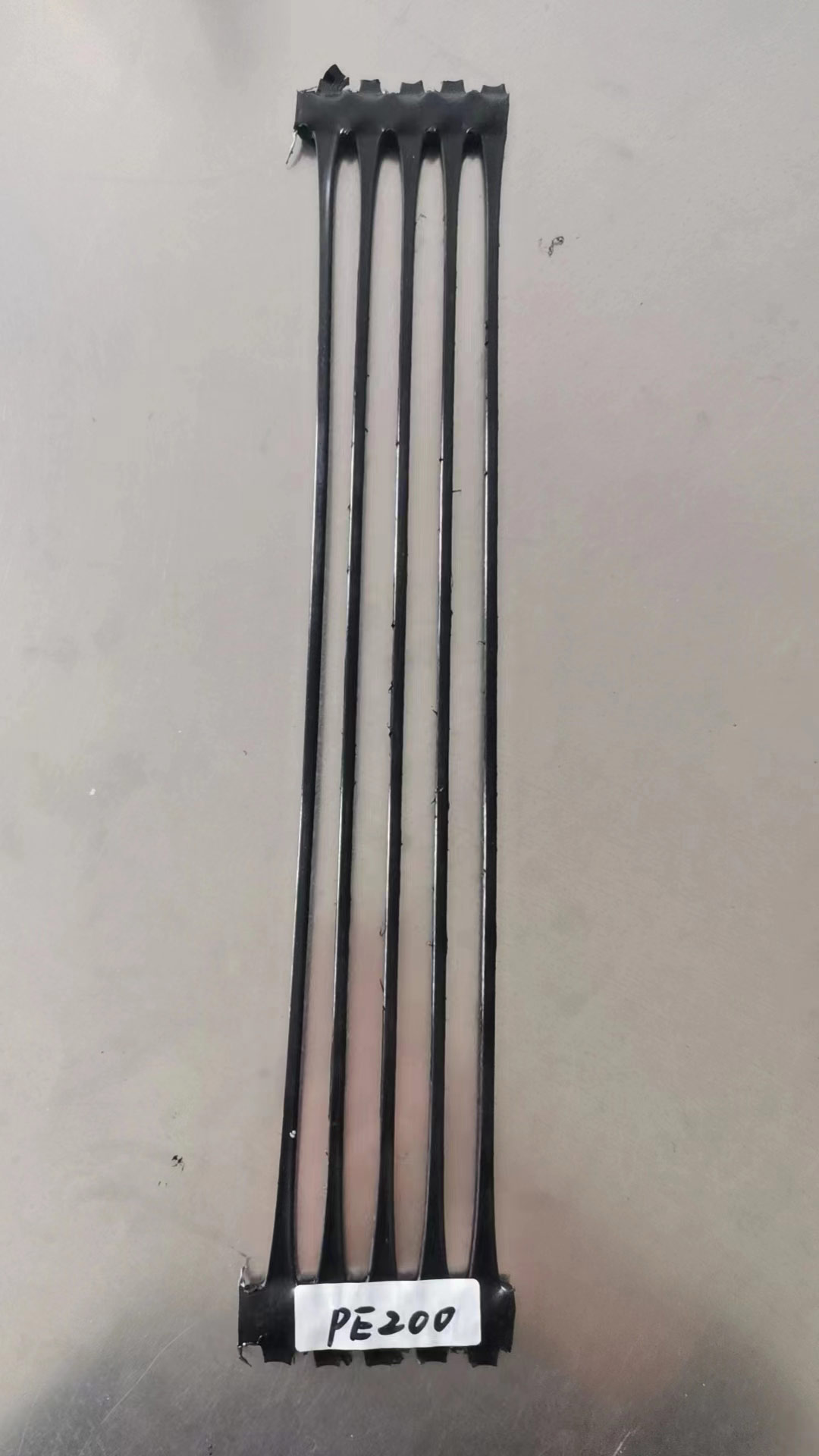

Uniaxial Plastic Geogrid

1. Good weather resistance: uniaxial geogrid is made of special plastic materials, with excellent weather resistance, can be used in various harsh climatic conditions for a long time, and is not easy to be affected by ultraviolet rays, acids and alkalis and other external environmental impacts and damage.

2. Lightweight and easy to transport: compared with traditional metal grating, uniaxial geogrid is lightweight and easy to transport and install. This not only improves the construction efficiency and reduces the cost, but also reduces the pressure on the soil and the risk of foundation settlement and deformation.

3. High strength and impact resistance: uniaxial geogrid is made of high-strength plastic material with excellent tensile, compressive and impact resistance. It can effectively support and disperse the load, enhance the stability of the soil and improve the safety and reliability of the project.

4. Good permeability and drainage: uniaxial geogrid has an open structure and good permeability, which allows water and air to circulate freely and does not impede the exchange of water and gas in the soil. At the same time, the gaps formed between the uniaxial geogrid can also effectively drain water, reducing the risk of waterlogging and soil erosion.

Product description

Uniaxial geogrid is a kind of high polymer as the main raw material, adding certain anti-ultraviolet, anti-aging additives, after one-way stretching to make the original distribution of scattered chain molecules re-directional arrangement of linear state, by extrusion and then punching the rules of the hole mesh, and then longitudinally stretched and become high-strength geosynthetics. This process makes the polymer into a directional linear state and the formation of a uniform distribution, high node strength of the long oval mesh integral structure. This structure has a fairly high tensile strength and tensile modulus, tensile strength of 100-200Mpa, close to the level of mild steel, greatly superior to the traditional or existing reinforced materials, especially such products of the company more than the international level of high early (elongation of 2% -5%) tensile strength and tensile modulus. To the soil provides the ideal force bearing and diffusion of the interlocking system. The product tensile strength (> 150Mpa), to adapt to a variety of soils, is now widely used reinforcing reinforcement materials. Its main features are: high tensile strength, good creep performance, convenient construction and low price.

Uniaxial geogrid is made of polymer (PP - polypropylene uniaxial geogrid or HDPE - high density polyethylene uniaxial geogrid extruded and pressed into a thin plate and then punched rules of holes in the network, and then longitudinally stretched and become. This process makes the polymer into a directional linear state and the formation of a long oval mesh integral structure with uniform distribution and high nodal strength.

Product Parameter

Project | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG150 | TGDG180 | TGDG200 | TGDG260 | TGDG320 |

Tensile Yield Force Per Linear Metre kN/m | 35 | 50 | 80 | 110 | 150 | 180 | 200 | 260 | 320 |

Yield Elongation %≤ | 10 | ||||||||

Tensile Force at 2% Elongation kN/m≥ | 10 | 12 | 26 | 32 | 45 | 55 | 70 | 90 | 110 |

Tensile force at 5% elongation kN/m≥ | 20 | 28 | 48 | 66 | 90 | 110 | 120 | 180 | 210 |

Finished Length/m | 50-100 | ||||||||

Finished width/ m | 3 | ||||||||

Application

1. Uniaxial geogrid used to reinforce weak foundation: geogrid can quickly improve the foundation bearing capacity, control the development of settlement, the road grass-roots level of lateral limitation can effectively distribute the load to the wider sub-base level, thus reducing the thickness of the grass-roots level, reduce the cost of the project, shorten the construction period, extend the service life.

2. Uniaxial geogrid for reinforced asphalt or cement pavement: geogrid laid in asphalt or cement pavement at the bottom, can reduce the depth of rutting, prolong the fatigue life of the pavement, but also reduce the thickness of asphalt or cement pavement to save costs.

3. Uniaxial plastic geogrid used to reinforce the road embankment dam and retaining wall: the traditional road embankment, especially high road embankment filling often need to overfill and shoulder edge is not easy to compact, resulting in the later slope rainfall, collapse instability of the phenomenon from time to time, at the same time, need to use the slower slope, covers an area of large, retaining wall has the same problem, using geogrid on the road embankment slopes or retaining wall can be reinforced to reduce the two-part The use of geogrid to reinforce the embankment slope or retaining wall can reduce two per cent of the floor space, extend the service life and reduce the cost by 20-50%.

4. Uniaxial plastic geogrid used to reinforce the river and sea dike: can be made into gabions, and then with the grid and use, to prevent the dike washed by the sea caused by the collapse of the gabion has permeability, can slow down the impact of the waves, extend the life of the dike, save manpower and material resources, shorten the period of time.

5. Uniaxial plastic geogrid used to deal with landfill: geogrid and other soil synthesis materials used in combination to deal with landfill, can effectively solve the uneven settlement of the foundation, derived from the gas emissions and other issues, and can maximise the storage capacity of the landfill.

6. Special use of uniaxial plastic geogrid: low temperature resistance. The low-temperature resistant geogrid of Liantuo Company, after repeated hot and cold cycles of -45℃---50℃ for 200 times, all the performance indexes meet the requirements, and has been tested by Qinghai-Tibet Railway, which is suitable for the northern less frozen soil, rich frozen soil, and high ice-containing permafrost adverse geology.