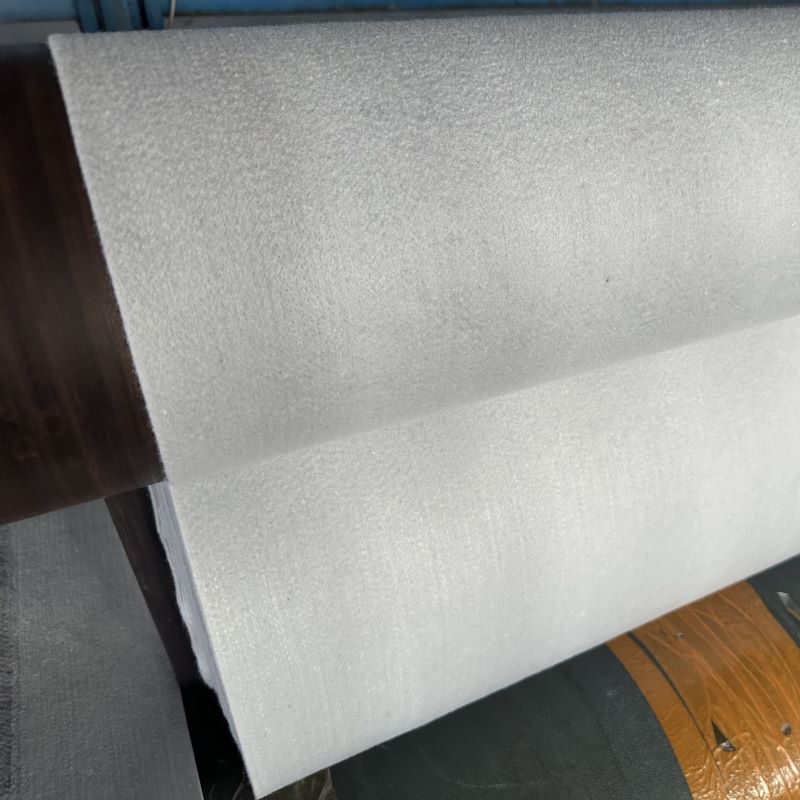

Geotextile Filter Fabric

Geotextiles have been widely used in various engineering projects over the past thirty years due to their excellent mechanical properties. These advanced geotextiles have excellent isolation, anti-seepage, drainage and reinforcement functions, far exceeding the performance of ordinary polypropylene geotextiles. Their good hydrophobicity further enhances their durability and application effect. From infrastructure construction to environmental protection, geotextiles have proven to be a reliable and long-lasting solution that can meet the high requirements of modern engineering practice.

Geotextile Filter Fabric excels in engineering and environmental protection, offering durability, recyclability, and pollution-free performance.With its multifunctionality and environmental benefits, Geotextile Filter Fabric has become an essential material in modern engineering and environmental protection, providing reliable support for sustainable development.

Application Scenarios:

Geotextile Filter Fabric is widely used in various engineering and environmental scenarios, including:

Road and Railway Engineering: Used for subgrade isolation, drainage, and reinforcement to prevent soil erosion and extend service life.

Hydraulic Engineering: Applied in dams, channels, and reservoirs for anti-seepage, filtration, and drainage, ensuring structural stability.

Environmental Protection: Utilized in landfills, sewage treatment plants, and other sites for filtration and isolation to prevent pollutant dispersion.

Landscaping and Greening: Used for soil water retention, drainage, and plant root protection to promote vegetation growth.

Coastal Protection: Employed to prevent coastal erosion and protect shoreline structures.

Environmental Performance:

Recyclability: Made from eco-friendly materials such as polypropylene, some products can be recycled and reused, reducing resource waste.

Durability: Features excellent anti-aging and UV resistance properties, ensuring a long service life and minimizing environmental impact from frequent replacements.

Pollution-Free: The materials are non-toxic and harmless, posing no risk to soil, water sources, or the ecological environment.

Energy Efficiency: Replaces traditional materials in engineering projects, reducing construction energy consumption and improving project efficiency.

Table 1 Physical and mechanical properties requirements of geotextiles | ||||

S/N | index | unit | Performance parameters and deviations | |

700g /㎡ | 600 g/㎡ | |||

1 | Tensile strength | kN/m | Vertical ≥48 Horizontal ≥48 | Vertical ≥40 Horizontal≥40

|

2 | Elongation | % | Vertical and horizontal 70 ±20 | Vertical and horizontal 60±20 |

3 | Burst strength | kN | ≥8.5 | ≥7.0 |

4 | Trapezoidal tear strength | N | Vertical and horizontal ≥900 | Vertical and horizontal≥700 |

5 | Acid and alkali resistance | % | Strength retention rate≥90 Elongation at break retention rate≥90

| |

6 | Abrasion resistance | % | Strength loss rate≤25 | Strength loss rate≤20 |

Table 2 Appearance defect evaluation | ||||

S/N | Defect name | Minor defect | Major defect | Remarks |

1 | Uneven fabric, creases | Slight

| Serious

| |

2 | Debris, stiff threads | Soft, rough ≤3 mm | Hard, soft, rough>3 mm | |

3 | Poor edges | ≤3 000 mm, count one point for every 500 mm

| >3 000 mm | |

4 | Damage | ≤5 mm | >5 mm; holes | Measured by the maximum length of defects |

Other | Evaluation with reference to similar defects | |||