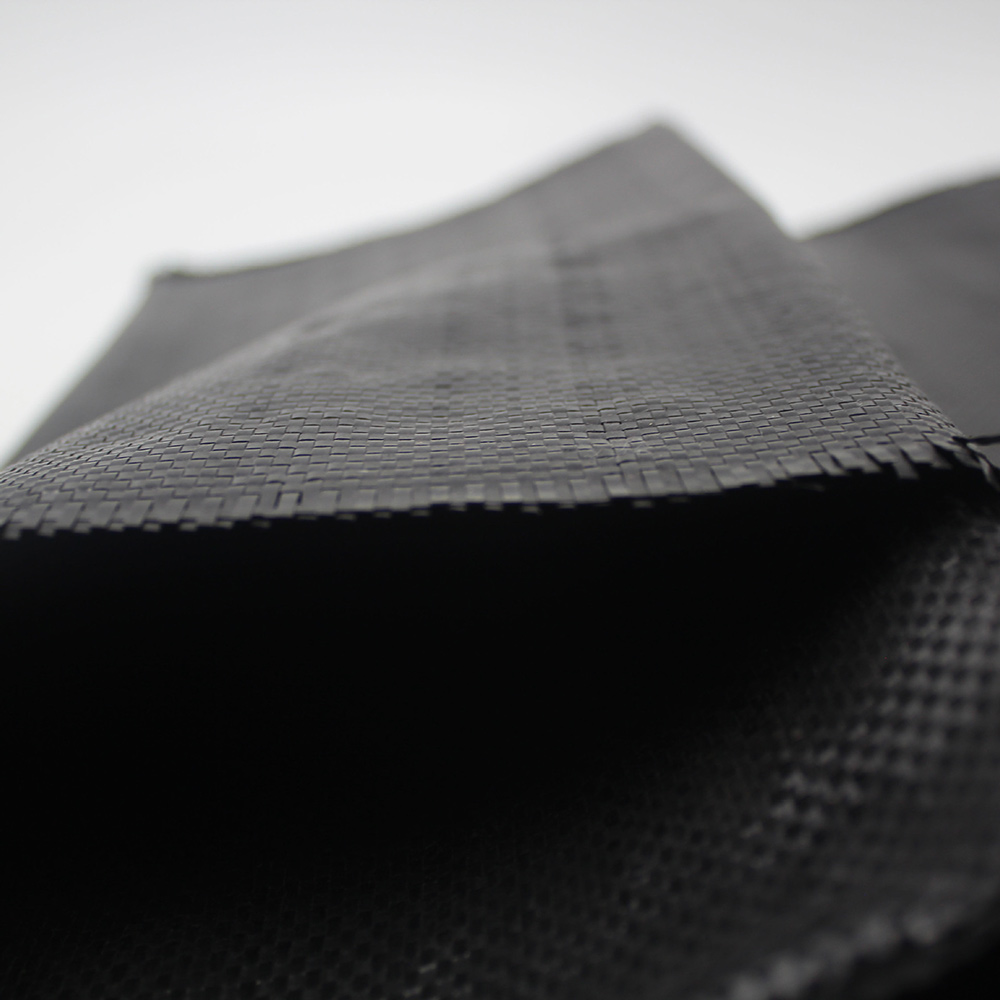

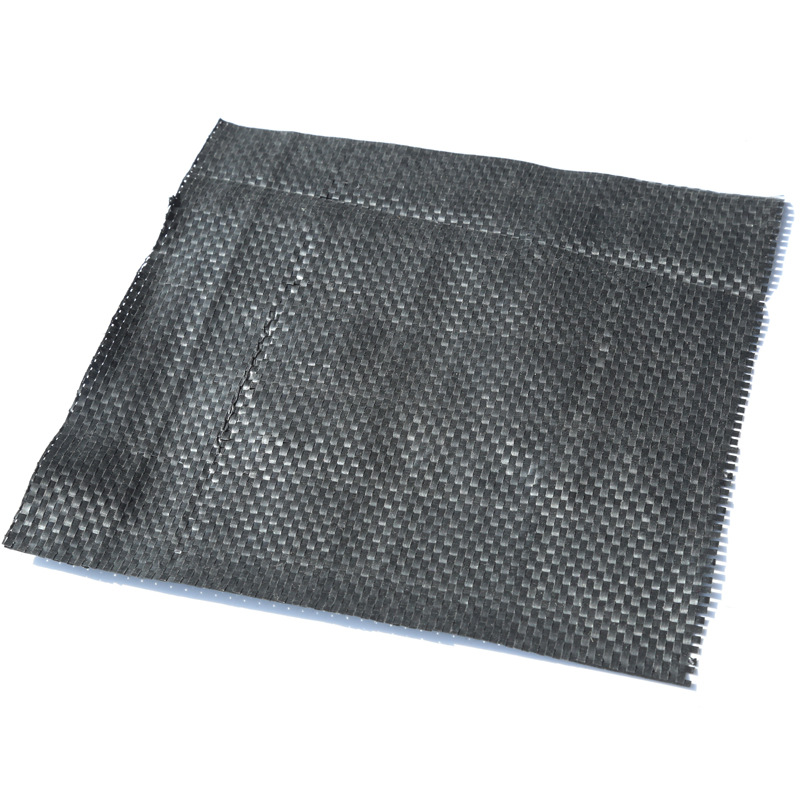

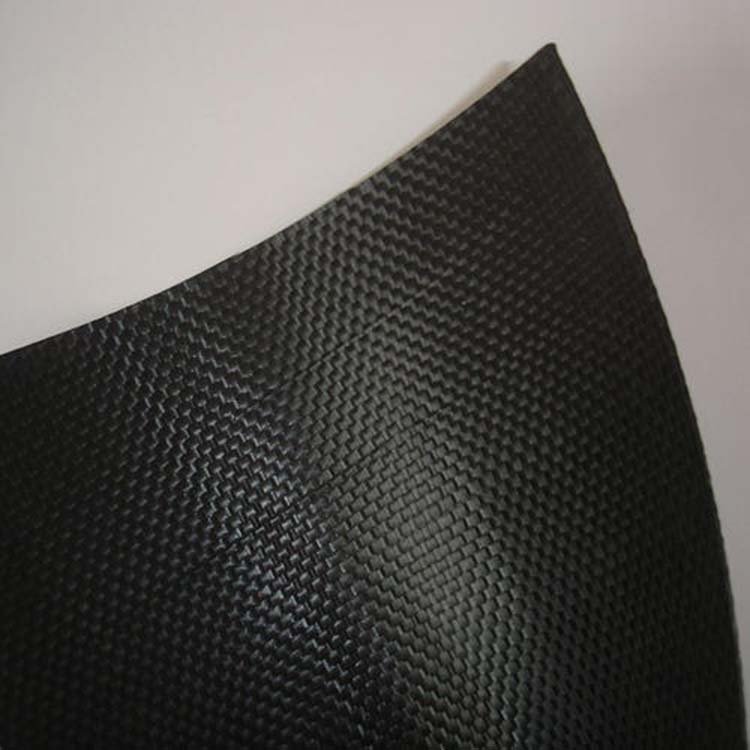

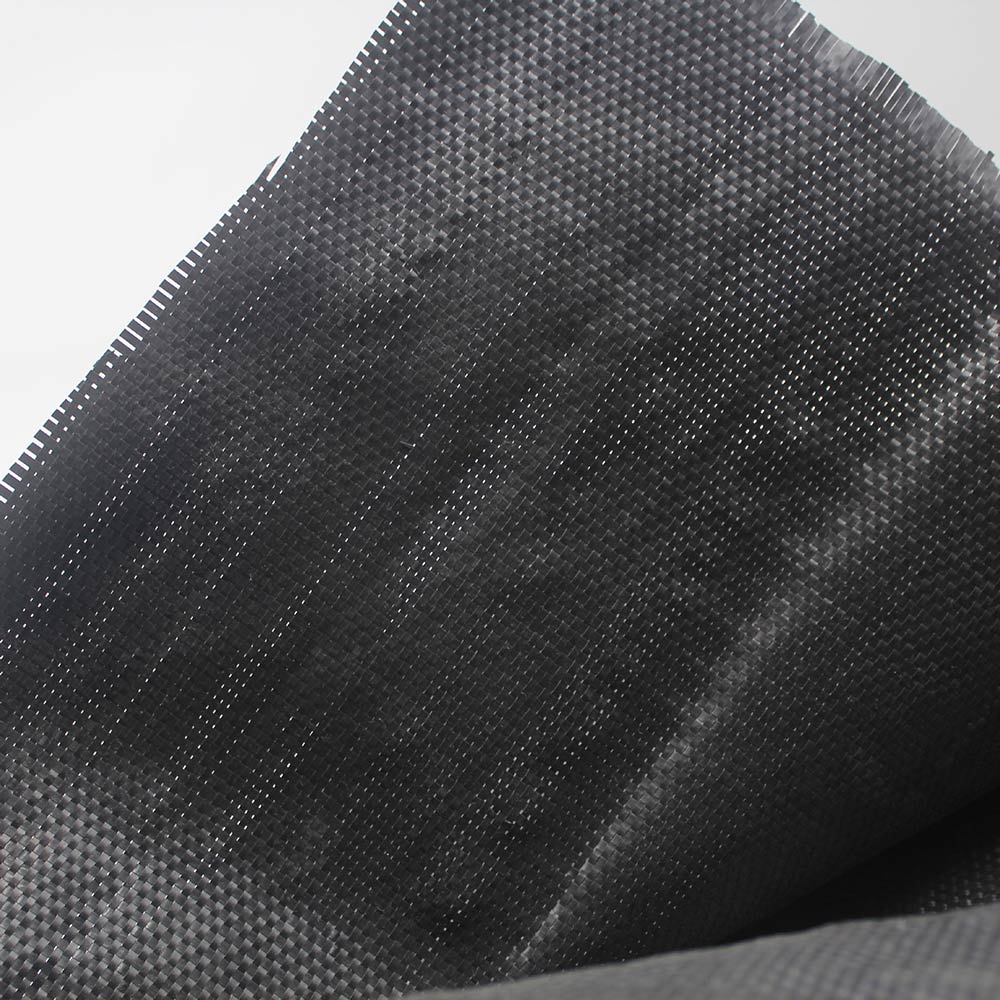

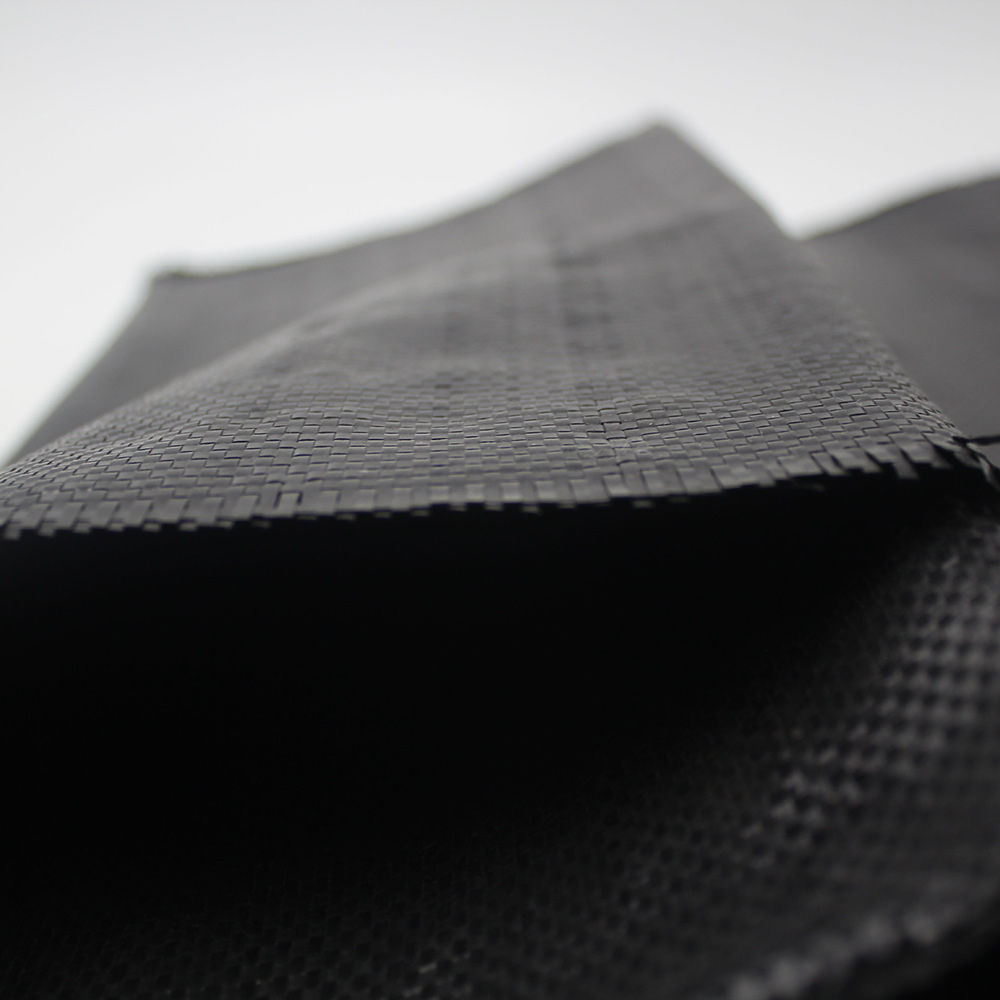

Polypropylene Woven Geotextile

Woven geotextile product performance

1. Reinforcement effect: used for highway, railway, airport, stone dam, slope embankment, retaining wall backfill, side of the reservoir and other rock projects, dispersing soil stress to increase the modulus of the soil, limit the slip of the soil to improve stability.

2. Protection function: prevent the embankment from being washed by wind, wave, tide and rain, and used for bank protection, slope protection, bottom protection, preventing soil erosion.

3. Anti-filtration function: It is used in the filter layer of embankment, dam, river and coastal stone fast, soil slope and retaining wall, preventing sand and soil particles from passing through, while allowing water or air to pass freely.

Product description

Woven geotextile is made of polypropylene, polypropylene flat silk as raw material, consisting of at least two groups of parallel yarns (or flat silk), one group along the longitudinal loom (the direction of the fabric travelling) is called the warp, the other group of transverse arrangement is called the weft. With different preparation and weaving equipment and process of weaving the warp yarns and weft yarns woven together into cloth, according to the different scope of use woven into different thicknesses and densities, the general woven geotextile thin longitudinal and transverse have a fairly strong tensile strength (longitudinal greater than the latitude), has a very good stability of the performance.

Performance parameters of woven geotextile

Project | Standard | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |

Longitudinal breaking strength,KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Weft breaking strength,KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation at break, warp and weft,1%≤ |

28 | ||||||

Trapezoidal tearing strength (longitudinal),KN≥ | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

Damaged by groundless slander, KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical permeability coefficient,cm/s |

10-1-10-4 | ||||||

Equivalent pore size O95,mm | 0.08-0.5 | ||||||

Mass per unit area,g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Tolerance (allowed error) | ±10 | ||||||

UV strength retention rate,1%≥ | As designed or contracted | ||||||

Woven geotextile installation and construction precautions

1. The geotextile can only be cut with a geotextile knife (hook knife), such as cutting on the site, other materials must take special protective measures to prevent unnecessary damage to the geotextile due to cutting;

2. While laying the geotextile, all necessary measures must be taken to prevent damage to the layer of material below;

3. While laying the geotextile, care must be taken not to allow substances such as stones, large quantities of dust or moisture, etc., which are likely to damage the geotextile, which are likely to block the drains or filters, or which are likely to cause difficulties in the ensuing connections, to enter the geotextile or the underside of the geotextile;

4. After the installation is completed, all geotextile surfaces are visually inspected to identify all damaged landowners, marked and repaired, and to make sure that there are no foreign substances that can cause damage to the paved surfaces, such as broken pins and other foreign objects;

5. The connection of geotextile must follow the following provisions: under normal circumstances, there can be no horizontal connection on the slope (the connection shall be along the contour of the slope does not intersect with it), except for the place of repair.

6. If sewing is used, the sewing line shall be made of the same or more than the same material as the geotextile, and the sewing line shall be made of chemical UV-resistant material. The stitching line and geotextile should have obvious colour difference for inspection.

7. Pay special attention to the stitching during installation to ensure that no soil or gravel in the gravel cover layer enters the middle of the geotextile.