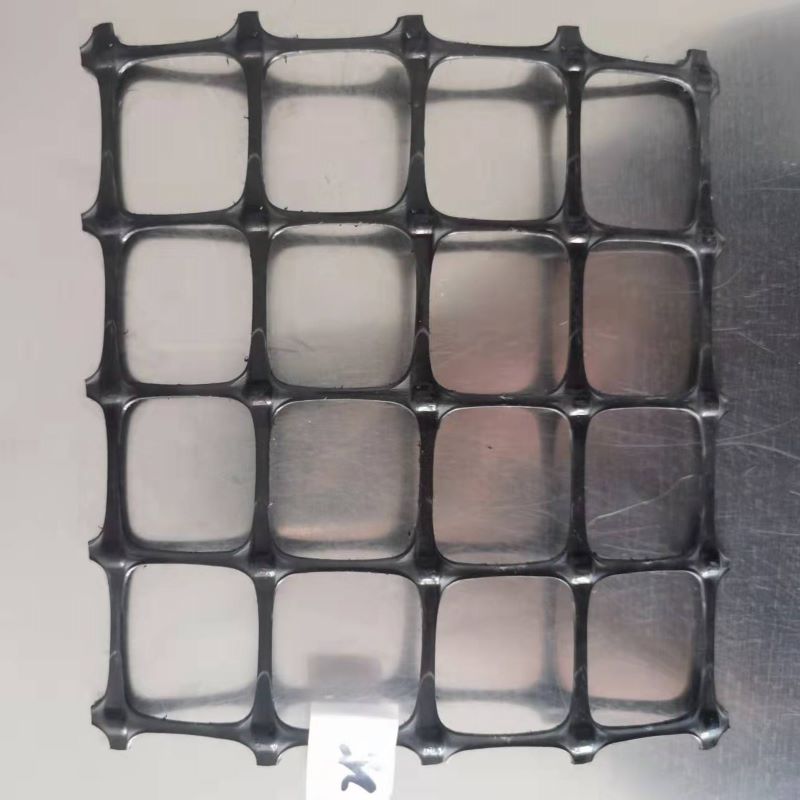

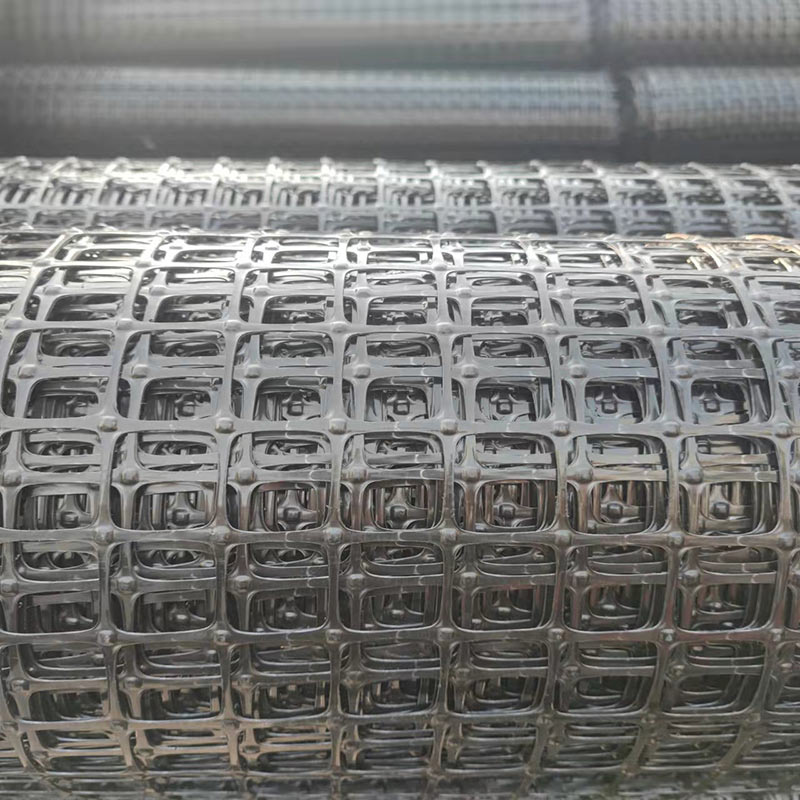

PP Biaxial Geogrid

PP Biaxial Geogrid is suitable for all kinds of embankment and roadbed reinforcement, slope protection, cave wall reinforcement, large airports, car parks, wharf yards and other permanent bearing foundation reinforcement.

1. Increase the bearing capacity of road (ground) foundation, extend the service life of road (ground) foundation. 2. prevent the road (ground) surface from being damaged.

2. Prevent the road (ground) surface from collapsing or cracks, and keep the ground beautiful and neat. 3.

3. Convenient construction, time-saving, labour-saving, shorten the construction period, reduce the maintenance cost.

4. Prevent culvert from cracking.

5. Enhance soil slope and prevent soil erosion.

6. reduce the thickness of bedding layer and save the cost.

7. support the stability of slope grass mesh mat green environment

8. Biaxial plastic geogrid is used in special net for animal husbandry and special net for fish farming.

9. Biaxial plastic geogrid is used for mine and pit reinforcement.

PP Biaxial Geogrid are made from polymers that are extruded, sheeted and perforated through a process followed by longitudinal and transverse stretching. The material has great tensile strength in both longitudinal and transverse directions, this structure in the soil can also provide a more effective force bearing and diffusion of the ideal interlocking system, adapted to a large area of permanent bearing foundation reinforcement.

Biaxial plastic geogrid is suitable for all kinds of embankment and roadbed reinforcement, slope protection, cave wall reinforcement, large airports, car parks, wharf yards and other permanent bearing foundation reinforcement.

Product parameters

Project | TGSG15-15 | TGSG20-20 | TGSG25-25 | TGSG30-30 | TGSG40-40 | TGSG45-45 | TGSG50-50 |

Longitudinal tensile yield force,kN/m | 15 | 20 | 25 | 30 | 40 | 45 | 50 |

Transverse tensile yield force, kN/m | 15 | 20 | 25 | 30 | 40 | 45 | 50 |

Longitudinal yield elongation, % | 13 | ||||||

Transverse elongation at yield, % | 13 | ||||||

Tensile at 2% elongation in the longitudinal direction, kN/m | 5 | 7 | 9 | 10.5 | 14 | 16 | 17.5 |

Tensile at 2% elongation in the transverse direction, kN/m | 5 | 7 | 9 | 10.5 | 14 | 16 | 17.5 |

Tensile at 5% elongation in the longitudinal direction, kN/m | 7 | 14 | 17 | 21 | 28 | 32 | 35 |

Tensile at 5% elongation in the transverse direction, kN/m | 7 | 14 | 17 | 21 | 28 | 32 | 35 |

Finished length,m | 50 | ||||||

Finished width, m | 4/6 | ||||||