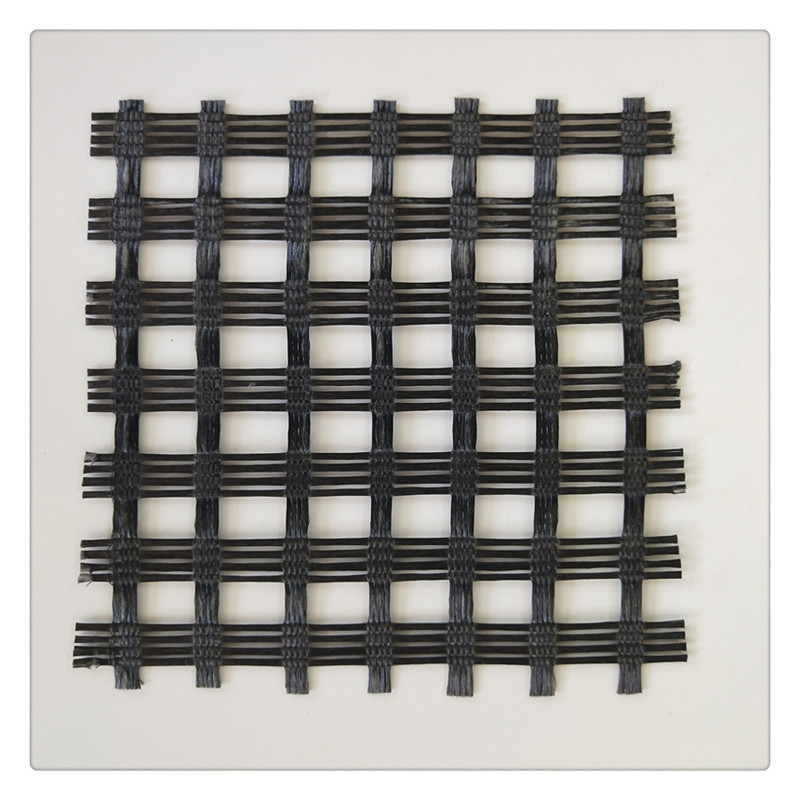

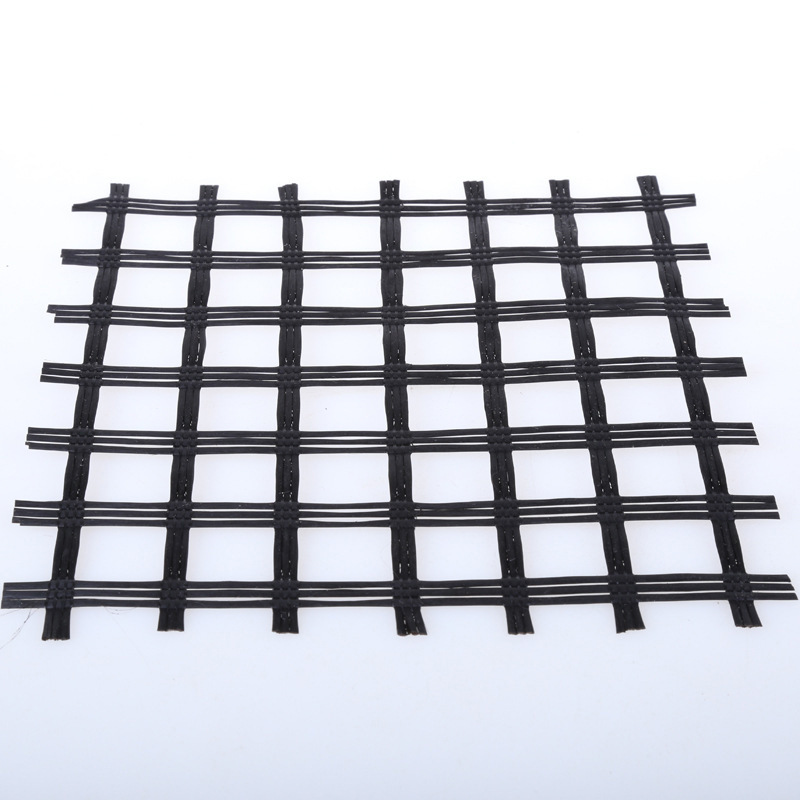

Warp Knitted Grille

Warp Knitted Grille, made from high-strength polyester or fiberglass via warp-knitting technology, offers exceptional tensile strength (50–200 kN/m), anti-creep performance, and bidirectional load distribution to prevent soil displacement. UV-resistant and corrosion-proof, it lasts over 30 years outdoors while maintaining permeability and soil stability. Ideal for highways, dams, mines, and more. Factory-direct sales eliminate middlemen, ensuring quality control, competitive pricing, and customizable production with rapid response. A cost-effective, durable reinforcement solution for infrastructure projects, enhancing efficiency and reducing long-term costs.

1. Core Functions & Advantages

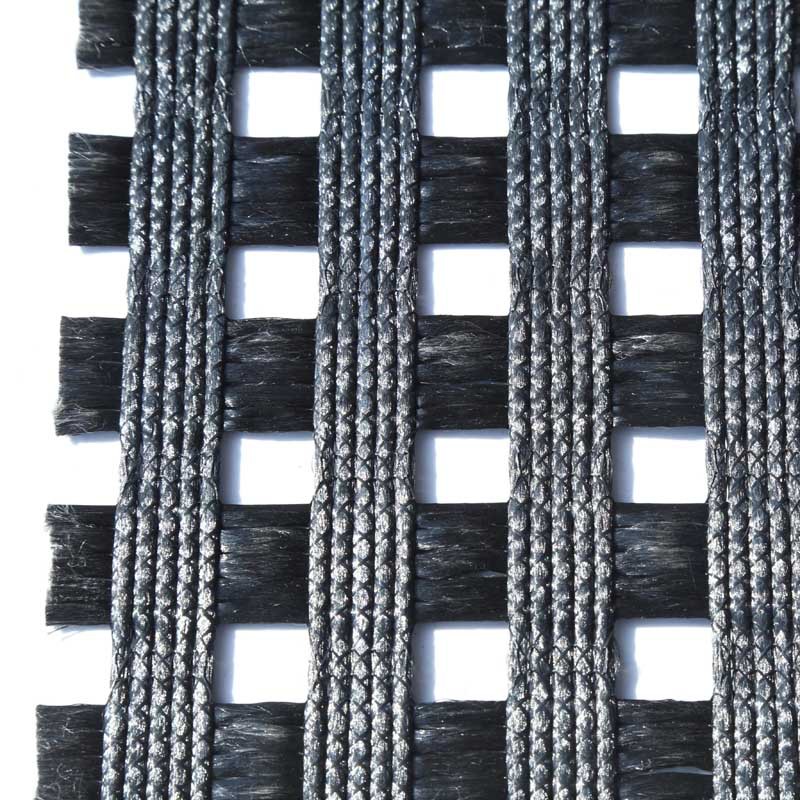

High Strength & Low Creep: Warp-direction tensile strength ranges from 50–200 kN/m, with minimal deformation under sustained loads, suitable for long-term stability in roadbeds and slopes.

Bidirectional Load Distribution: The grid structure evenly disperses stress, reducing localized concentration and preventing soil lateral displacement.

Corrosion & UV Resistance: Polyester fibers coated with PVC or asphalt resist chemical erosion and UV degradation, ensuring a service life of over 30 years in exposed conditions.

Permeability & Soil Retention: Open mesh allows water flow while retaining soil particles, maintaining structural integrity.

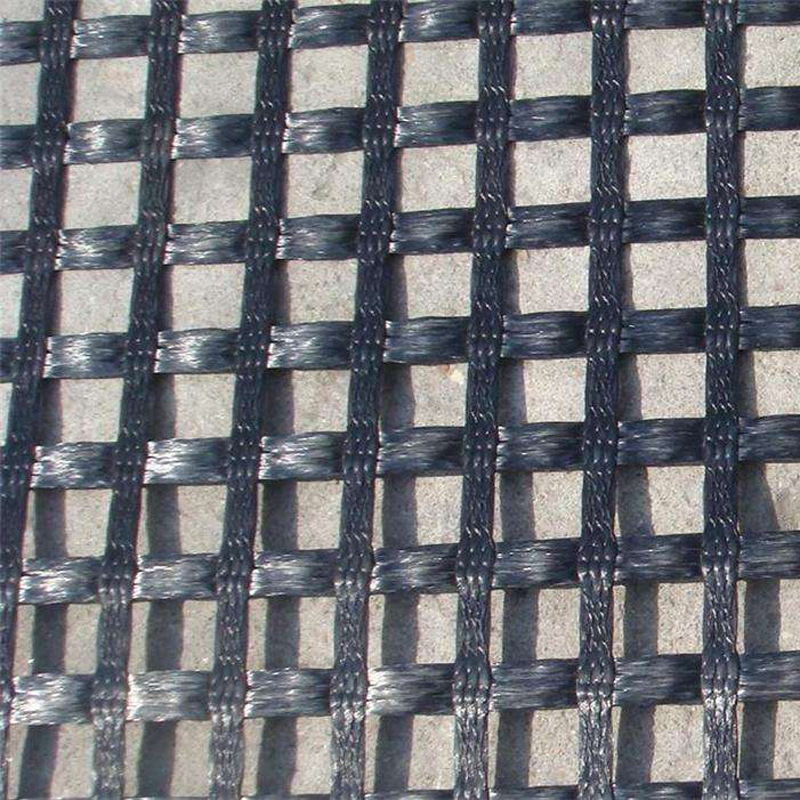

2. Typical Applications

Transportation Infrastructure:

Soft soil reinforcement for highways/railways to prevent settlement.

Base reinforcement for airport runways to enhance load-bearing capacity.

Hydraulic Engineering:

Reinforcement of dam slopes and riverbanks to withstand erosion.

Retaining wall backfill stabilization to reduce earth pressure.

Environmental Remediation:

Stability enhancement for mine tailings ponds.

Ecological slope protection to support vegetation growth and soil fixation.

Industrial Use:

Ground reinforcement for container yards to handle heavy machinery loads.

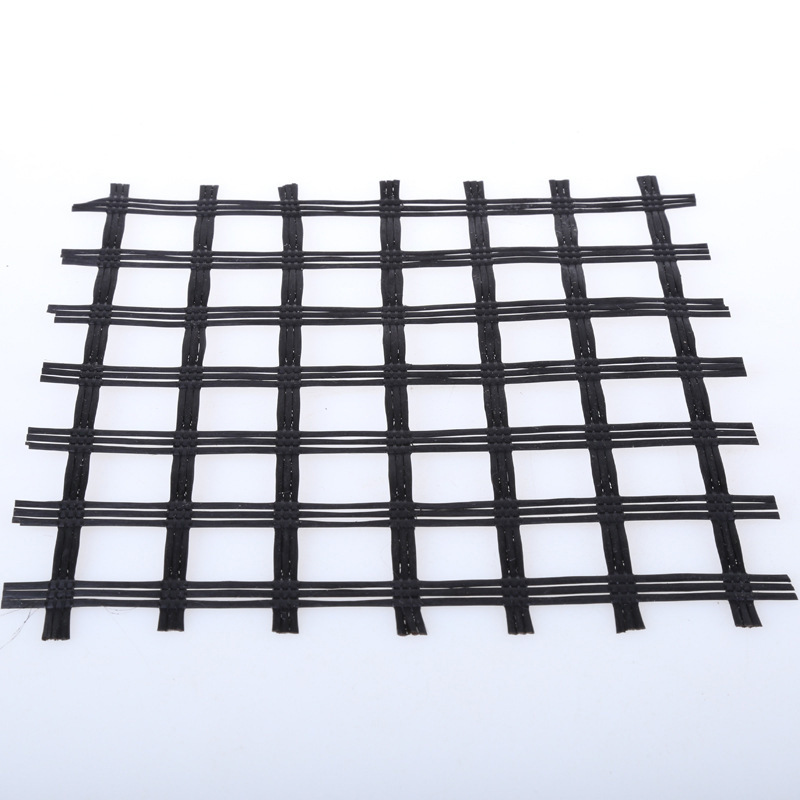

3. Selection & Installation Guidelines

Selection Criteria: Choose aperture size (10–50 mm) and tensile strength based on load requirements and soil type (e.g., clay, sand).

Installation Standards:

Level the subgrade before laying to avoid damage from sharp objects.

Overlap adjacent rolls by 10–15 cm and secure with U-pins or connectors.

Compact fill materials (e.g., gravel) between layers for synergistic load distribution.