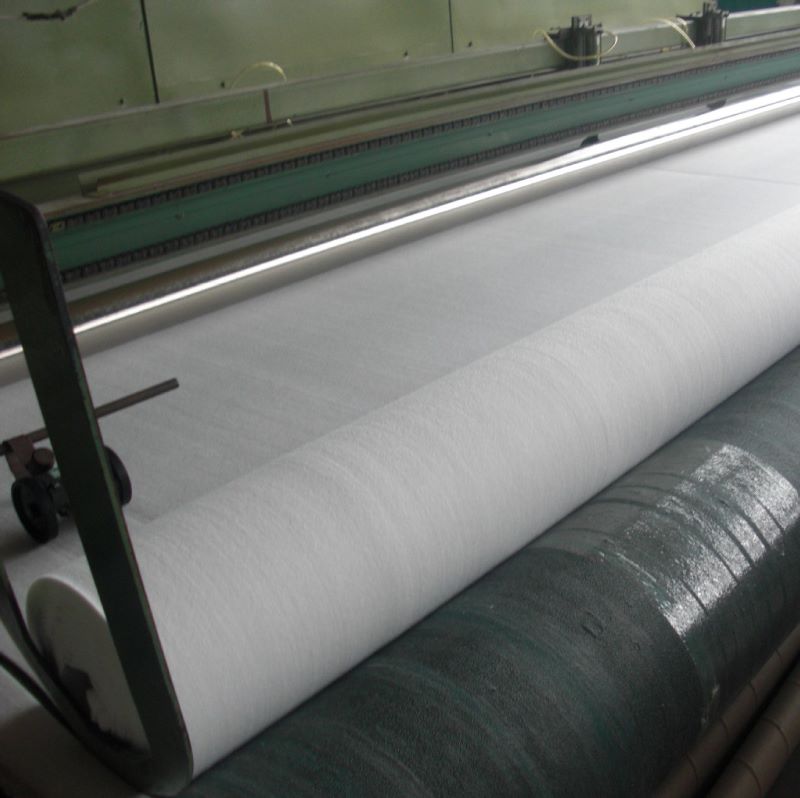

Short Fiber Geotextile

Short fiber geotextiles are versatile and reliable materials that offer a range of benefits in civil engineering and construction applications. Their strength, durability, filtration efficiency, and ease of installation make them a valuable component in enhancing the performance and longevity of a wide variety of infrastructure projects.

Short Fiber Geotextile Product Overview

Introduction: Short fiber geotextile is a specialized geosynthetic material made from short fibers that are mechanically bonded together. It is commonly used in civil engineering and construction projects for various applications such as filtration, separation, drainage, and reinforcement.

Key Features:

Fiber Composition: Short fiber geotextiles are typically made from polypropylene or polyester fibers that are short in length and mechanically bonded to form a non-woven fabric structure.

Strength and Durability: Despite the short fiber length, these geotextiles offer excellent tensile strength, puncture resistance, and durability, making them suitable for withstanding construction stresses.

Filtration Efficiency: Short fiber geotextiles provide effective filtration by allowing water to pass through while retaining soil particles, preventing clogging and ensuring proper drainage.

Separation Function: Used to separate different soil layers and aggregate materials, short fiber geotextiles help prevent mixing and maintain the integrity of the construction layers.

UV and Chemical Resistance: These geotextiles are designed to resist UV degradation and exposure to chemicals, ensuring long-term performance in various environmental conditions.

Ease of Installation: Short fiber geotextiles are easy to handle and install, providing a cost-effective solution for improving the stability and longevity of construction projects.

Product Parameter

Project | Performance indicators | |||||||

Nominal Strength,kN/m | 5 | 8 | 11 | 20 | 24 | 28 | 34 | 50 |

Longitudinal and Transverse Tensile Breaking Strength,kN/m | ≥5.0 | ≥8.0 | ≥11.0 | ≥20.0 | ≥24.0 | ≥28.0 | ≥34.0 | ≥50.0 |

Longitudinal and Transverse Elongation At Break | 50%~90% | |||||||

Longitudinal and Transverse Tearing Strength, kN | ≥0.15 | ≥0.24 | ≥0.35 | ≥0.42 | ≥0.50 | ≥0.58 | ≥0.65 | ≥0.90 |

CBR Top Break Power, kN | ≥1.0 | ≥1.7 | ≥2.5 | ≥3.5 | ≥4.3 | ≥5.3 | ≥6.2 | ≥7.0 |

Vertical and Horizontal Grip Strength, kN | ≥0.3 | ≥0.6 | ≥0.9 | ≥1.3 | ≥1.7 | ≥2.0 | ≥2.4 | ≥3.0 |

Thicknesses, mm | ≥1.2 | ≥1.6 | ≥1.8 | ≥2.4 | ≥2.8 | ≥3.0 | ≥3.2 | ≥3.4 |

Equivalent Pore Size, ο95 mm | 0.07~0.20 | |||||||

Vertical Permeability Coefficient,cm/s | ≤2.0×10-1 | |||||||

UV Strength Retention Rate | ≥80% | |||||||

Mass Per Unit Area,g/m2 | ≥100 | ≥150 | ≥200 | ≥300 | ≥400 | ≥500 | ≥600 | ≥800 |

Quality Deviation Per Unit Area | ±5% | ±4% | ±3% | |||||

Width Deviation | ±0.5% | |||||||

Tensile Strength of Geobags At Seams,kN/m | — | ≥6.5 | ≥9.0 | ≥16.0 | — | — | — | — |

Applications:

Road Construction: Short fiber geotextiles are commonly used in road construction projects as a separation layer between the subgrade and base materials, enhancing the road's durability and performance.

Drainage Systems: Applied in drainage systems, these geotextiles prevent soil clogging, promote water flow, and protect the integrity of the drainage infrastructure.

Erosion Control: Used in erosion control applications, short fiber geotextiles help stabilize slopes, prevent soil erosion, and protect the environment from water runoff.

Landfill Engineering: Short fiber geotextiles play a vital role in landfill engineering by providing a protective barrier between waste materials and the underlying soil, preventing contamination and promoting proper drainage.