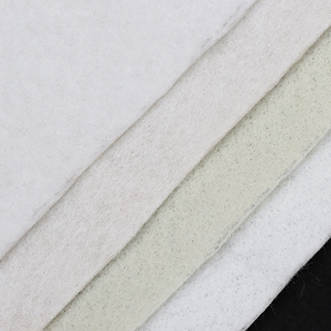

Polyester Non-woven Geotextile

1. Strong tensile strength: geotextile has very high tensile strength, can withstand large tensile force, to ensure the stability of the structure.

2. Good erosion resistance: geotextile has good erosion resistance to water and soil, which can effectively prevent soil loss and erosion, and protect the stability of the ground.

3. Good water permeability and air permeability: geotextile has good water permeability and air permeability, which can make water penetrate quickly, avoid waterlogging and prevent water stagnation in the soil, which is good for plant growth.

4. Long-term stability: geotextile has high chemical stability, can withstand the influence of the external environment for a long time, and is not easy to change the quality.

5. Easy to install and maintain: Geotextile is lightweight, soft, easy to carry and install, but also easy to maintain and repair.

6. High plasticity: geotextile can be cut, sewn and connected according to engineering needs, and can adapt to various complex terrain and geological conditions.

7. Environmentally sustainable: geotextiles are made of synthetic fibres with good durability and reusability, which can reduce resource consumption and environmental pollution.

Product description

Geotextile, also known as geotextile, is a permeable geosynthetic material made from synthetic fibres by needling or weaving. The finished product is in the form of cloth, generally 4-6 metres in width and 50-100 metres in length. Geotextile is divided into spun geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage control, protection, light weight, high tensile strength, good permeability, high temperature resistance, freezing resistance, aging resistance, corrosion resistance.

Geotextile is one of the geosynthetics, the application of geosynthetics originated in the 1950s of the twentieth century, the domestic geotextile is one of the country's eighty-five plan, China in 1998 promulgated the "geosynthetics staple fibre needle punched non-woven geotextile" (GB/T17638-1998) standard, at present, the geotextile has been widely used in many fields. It is a new type of construction material, the raw material is polyester, polypropylene, acrylic, polyamide and other polymer synthetic fibres. According to the manufacturing method is divided into: spun geotextile and non-woven geotextile two types. General engineering is mainly used non-woven geotextile. Geotextile has anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it is compared with conventional stone masonry and concrete material seepage control effect, has a low investment, simple construction process, short construction period, seepage control effect is good, the effective use of channel coefficient and other advantages.

The American Society of Agricultural Engineers defines a geotextile as a geotextile or geosynthetic material that exists between the soil and a pipe, gabion, or retaining wall that enhances the movement of water and impedes the movement of soil. ASTM 4439 defines a geotextile as a purely permeable geosynthetic composition textile. It is used in soil, rock, clay, or other geotechnical related materials and performs a structural function as a component of a human-made item.

Product parameter

Project | Performance Indicators | |||||||||||||

Nominal Strength,kN/m | 2.5 | 4.5 | 6.5 | 9.5 | 12.5 | 16.0 | 19.0 | 25.0 | ||||||

Longitudinal and Transverse Tensile Breaking Strength, kN/m | ≥2.5 | ≥4.5 | ≥6.5 | ≥9.5 | ≥12.5 | ≥16.0 | ≥19.0 | ≥25.0 | ||||||

Longitudinal and Transverse Elongation At Break | 25%~100% | |||||||||||||

Vertical Or Horizontal Tearing,kN | ≥0.08 | ≥0.12 | ≥0.16 | ≥0.24 | ≥0.33 | ≥0.42 | ≥0.46 | ≥0.60 | ||||||

CBR Top Break Power,kN | ≥0.3 | ≥0.6 | ≥0.9 | ≥1.5 | ≥2.1 | ≥2.7 | ≥3.2 | ≥4.0 | ||||||

Vertical and Horizontal Grip Strength,kN | ≥0.18 | ≥0.26 | ≥0.34 | ≥0.50 | ≥0.70 | ≥0.95 | ≥1.10 | ≥1.30 | ||||||

Thicknesses | ≥0.9 | ≥1.3 | ≥1.7 | ≥2.4 | ≥3.0 | ≥3.6 | ≥4.1 | ≥5.0 | ||||||

Equivalent Pore Size○95,mm | 0.07~0.20 | |||||||||||||

Vertical Permeability Coefficient,cm/s | 1.0×(100~10-3) | |||||||||||||

UV Strength Retention Rate | ≥80% | |||||||||||||

Mass Per Unit Area,g/m2 | ≥100 | ≥150 | ≥200 | ≥300 | ≥400 | ≥500 | ≥600 | ≥800 | ||||||

Quality Deviation Per Unit Area | ±5% | ±4% | ±3% | |||||||||||

Width Deviation | ±0.5% | |||||||||||||

The role of geotextiles

1. Separation

The use of polyester staple fibre needle punched geotextile to have different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.).

Material (such as soil and sand, soil and concrete, etc.) to isolate. So that two or more kinds of materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the carrying capacity of the structure to strengthen.

2. Filtration (back-filtration)

When water flows into the coarse material soil layer from the fine material soil layer, using polyester staple fibre needle punched geotextile's good air permeability and water permeability, so that the water flow through, while effectively carrying soil particles, fine sand, small stones, etc., in order to maintain the stability of the soil and water works.

3. Drainage

Polyester staple fibre needle punched geotextile has good water conductivity, it can form drainage channel inside the soil body, the excess liquid and gas drainage within the soil structure.

4. Reinforcement

Polyester staple fibre needle punched geotextile is used to enhance the tensile strength and deformation resistance of the soil body, to enhance the stability of the building structure, in order to improve the quality of the soil body.

5. Protection

When the soil is washed by water flow, it can effectively diffuse, transfer or decompose the concentrated stress to prevent the soil from being damaged by external force and protect the soil.

6. Anti-puncture

Combined with geomembrane to become a composite waterproof seepage control material, play the role of anti-puncture. High tensile strength, good permeability, air permeability, high temperature resistance, freezing resistance, aging resistance, corrosion resistance, not worm. Polyester staple fibre needle punched geotextile is a widely used geosynthetic material. Widely used in railway roadbed reinforcement, highway pavement maintenance, sports halls, dam protection, isolation of hydraulic construction, attempt hole, coastal mudflats, reclamation, environmental protection and other projects.

Application

1. As reinforcement in the backfill of retaining walls, or for anchoring panels of retaining walls. To build parcel retaining walls or bridge abutments. Application of geotextiles in construction

2. Reinforcing flexible pavements, repairing cracks on roads, and preventing reflective cracks in pavements.

3. Increase the stability of gravel slopes and reinforced soil, and prevent soil erosion and frost damage of soil body at low temperature.

4. The isolation layer between road ballast and roadbed, or the isolation layer between roadbed and soft base.

5. Isolation layer between artificial fill, rock pile or material field and foundation, isolation between different frozen soil layers. Anti-filtration and reinforcement.

6. Filter layer on the initial upstream face of an ash storage dam or tailings dam, filter layer in the drainage system in the backfill of a retaining wall.

7. Filter layer around drainage culverts or gravel drainage culverts.

8. Filter layer of water wells, pressure reducing wells or inclined pressure pipes in water resources projects.

9. Separation layer of geotextile between highways, airports, railway tracks, artificial rock piles and foundations.

10. Vertical or horizontal drainage inside an earth dam, buried in the soil to dissipate void water pressure.

11. Drainage behind the impermeable geomembrane in the earth dam or earth embankment or the lower part of the concrete sheathing.

12. Excluding seepage water around the tunnel, reducing the external water pressure on the lining and seepage water around each building.

13. Drainage of the foundation of sports ground on artificially filled land.

14. It is used to strengthen the weak foundation in the project of highway (including temporary road) railway, embankment, earth and stone dam, airport and sports ground.