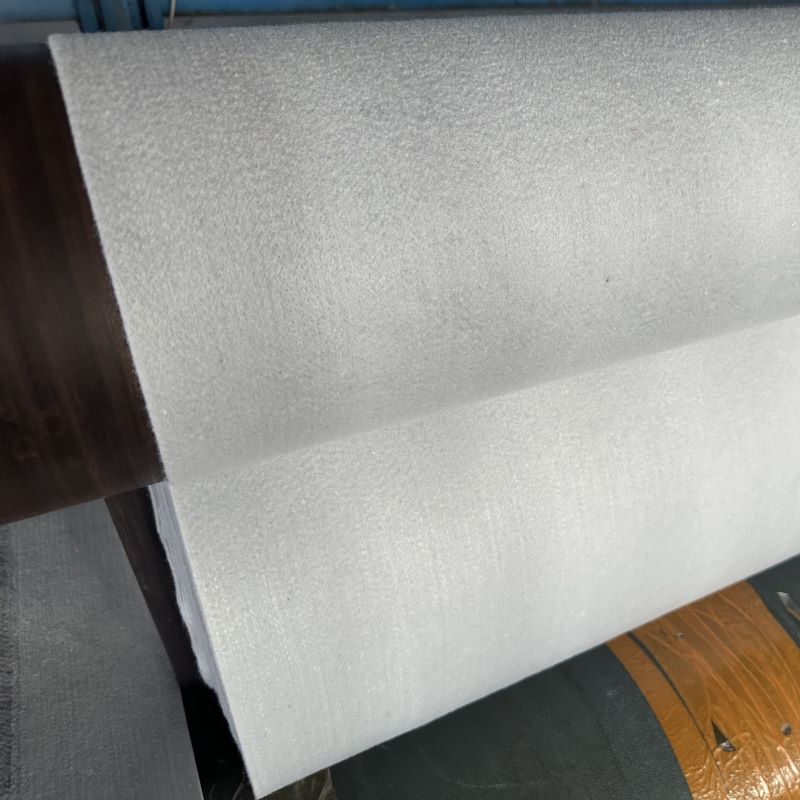

High Strength Polypropylene Geotextile

High-strength polypropylene geotextiles and other geotextiles with isolation, anti-filtration, drainage and reinforcing and other functions, with good hydrophobicity, compared with ordinary polypropylene geotextiles have better mechanical properties, more than 30 years, high-strength polypropylene geotextiles have been widely used in various projects.

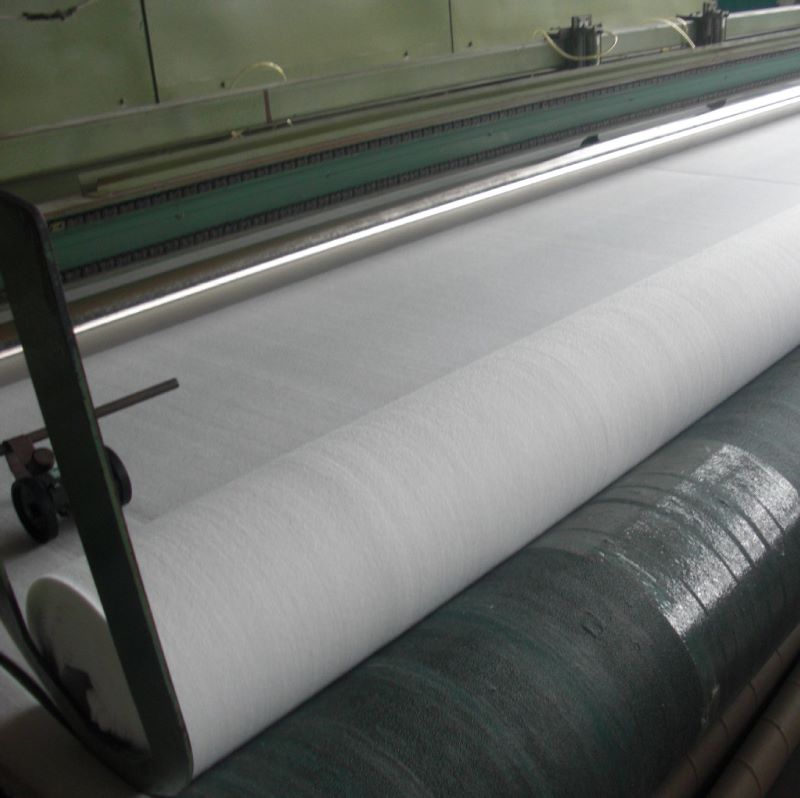

High-strength polypropylene staple fiber needled geotextile is made of high-strength polypropylene staple fiber as the main raw material, which is produced through the process of opening, carding, miscellaneous, laying mesh needled and spraying water repellent agent.

Product specification

SNGPP100~SNGPP1200 Width 2m~6m., length according to user requirements.

Product Parameter

Table 1 Physical and mechanical properties requirements of geotextiles | ||||

S/N | index | unit | Performance parameters and deviations | |

700g /㎡ | 600 g/㎡ | |||

1 | Tensile strength | kN/m | Vertical ≥48 Horizontal ≥48 | Vertical ≥40 Horizontal≥40

|

2 | Elongation | % | Vertical and horizontal 70 ±20 | Vertical and horizontal 60±20 |

3 | Burst strength | kN | ≥8.5 | ≥7.0 |

4 | Trapezoidal tear strength | N | Vertical and horizontal ≥900 | Vertical and horizontal≥700 |

5 | Acid and alkali resistance | % | Strength retention rate≥90 Elongation at break retention rate≥90

| |

6 | Abrasion resistance | % | Strength loss rate≤25 | Strength loss rate≤20 |

Table 2 Appearance defect evaluation | ||||

S/N | Defect name | Minor defect | Major defect | Remarks |

1 | Uneven fabric, creases | Slight

| Serious

| |

2 | Debris, stiff threads | Soft, rough ≤3 mm | Hard, soft, rough>3 mm | |

3 | Poor edges | ≤3 000 mm, count one point for every 500 mm

| >3 000 mm | |

4 | Damage | ≤5 mm | >5 mm; holes | Measured by the maximum length of defects |

| 5 | Other | Evaluation with reference to similar defects | ||

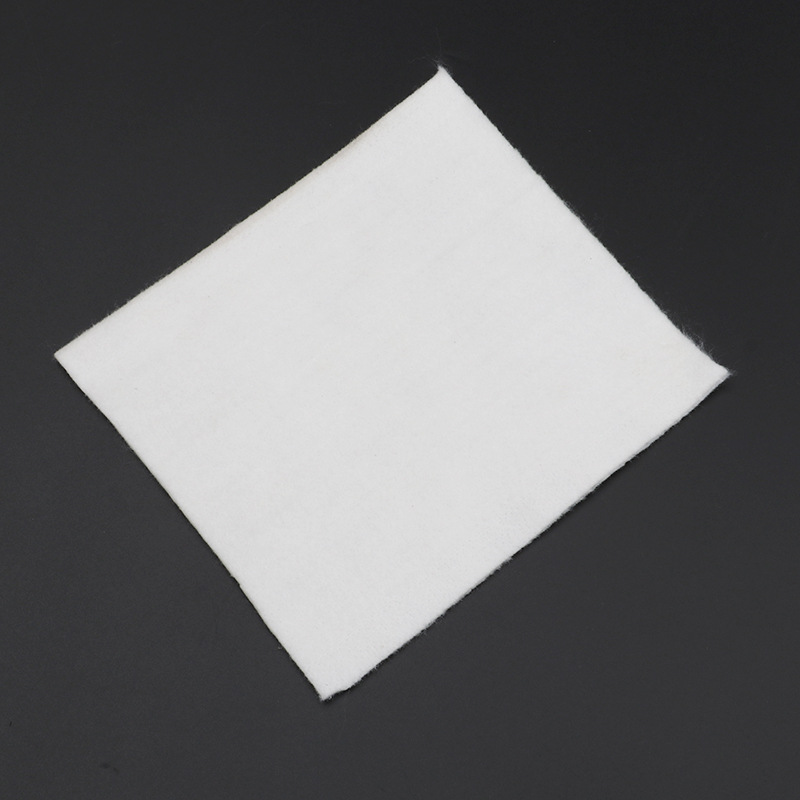

Features

The physical and mechanical properties such as breaking strength and anti-puncture strength have obvious advantages, which are 2 to 3 times higher than those of conventional products. The same grams of the product specific gravity is low; has good acid and alkali resistance and good hot-melt adhesion, good on-site processability, the ability to adapt to a variety of engineering conditions. Used in the components of CRTS Ⅱ type plate ballastless track system can reduce the interaction between the track system and the bridge surface.

|  |

| |

Application scope

polypropylene high-strength geotextile is mainly used for the sliding layer between CRTSⅡ type plate ballast track and girder surface and the isolation layer between CRTSⅡ plate ballast track and friction, and it can also be widely used in the fields of hydroelectricity, highway, railroad, harbor, airport, stadium, tunnel, coastal beach, reclamation, environmental protection, etc., which can play the roles of isolation, filtration, drainage, reinforcement, protection, closure, and so on. Closure, etc.