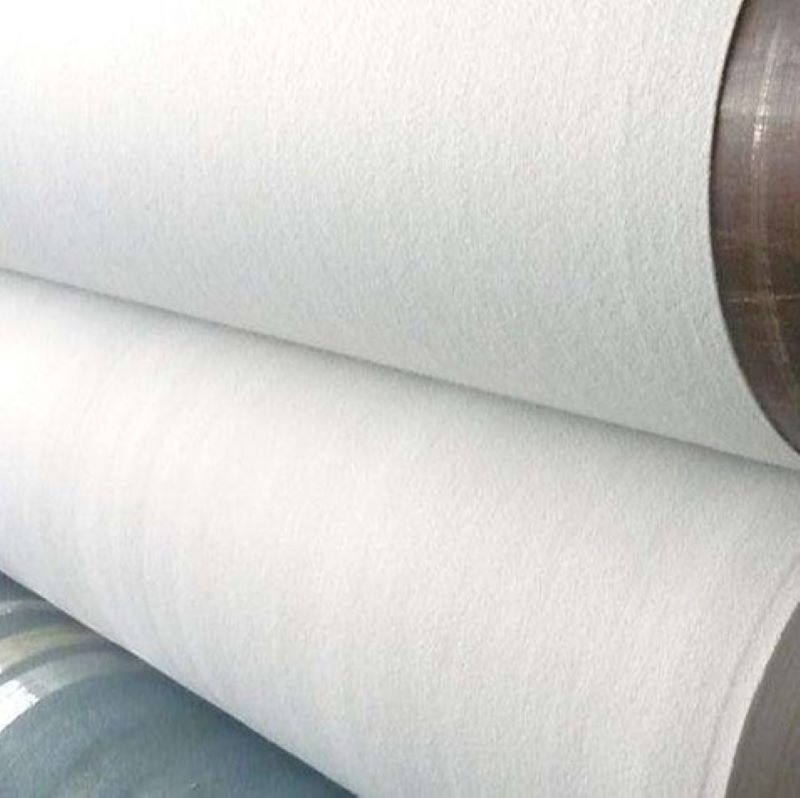

Hot Rolled Geotextile

1. Lightweight: polypropylene resin as the main raw material, specific gravity of only 0.9, only three-fifths of cotton, with fluffy, good feel.

2. Soft: composed of fine fibers (2-3D) light point-like hot melt bonding molding. The finished product is moderately soft, with a sense of comfort.

3. Water-repellent, breathable: polypropylene slices do not absorb water, water content of zero, the finished water-repellent good, composed of 100% fiber with porous, breathable, easy to keep the cloth dry, easy to wash.

4. Non-toxic, non-irritant: the product is produced with FDA food-grade raw materials, does not contain other chemical components, stable performance, non-toxic, no odor, does not irritate the skin.

5. Antibacterial, anti-chemicals: polypropylene is a chemical blunt substance, not insect, and can isolate the presence of bacteria and insects within the liquid erosion; antibacterial, alkali corrosion, the finished product does not affect the strength of erosion.

6. Antibacterial. Products with water pulling, not moldy, and can isolate the existence of bacteria and insects in the liquid erosion, not moldy.

7. Good physical properties. Spun by the polypropylene directly laid into a network of thermal bonding and become, the strength of the product is better than the general short-fiber products, the strength of non-directional, longitudinal and transverse strength is similar.

AProduct description

Hot rolling is the last geotextile production process into a network of technology, is cooled after the achievement of the fabric of a process, hot rolling is a high degree of heat (100 ~ 150 degrees) - rolling wheel rolled over the uniform fiber filaments to make the melting and thus into the network, so the hot rolled geotextile fabric surface will be rolled, similar to the same as the pinholes, but does not penetrate, the specific size of the mill wheel depends on the size of the steel thorns on the size and density. In summary, it is not difficult to conclude that, as a process, hot-rolled geotextile is not specific to a particular kind of cloth, but a class of geotextile after a similar process into a general term, in general, the use of hot-rolled process is spunbonded polypropylene geotextile (PP.), polyester geotextile (PET.), the two types of the biggest difference is that the processing of raw materials is different.

Product Parameter

Project | Performance indicators | |||||||

Nominal Strength,kN/m | 5 | 8 | 11 | 20 | 24 | 28 | 34 | 50 |

Longitudinal and Transverse Tensile Breaking Strength,kN/m | ≥5.0 | ≥8.0 | ≥11.0 | ≥20.0 | ≥24.0 | ≥28.0 | ≥34.0 | ≥50.0 |

Longitudinal and Transverse Elongation At Break | 50%~90% | |||||||

Longitudinal and Transverse Tearing Strength, kN | ≥0.15 | ≥0.24 | ≥0.35 | ≥0.42 | ≥0.50 | ≥0.58 | ≥0.65 | ≥0.90 |

CBR Top Break Power, kN | ≥1.0 | ≥1.7 | ≥2.5 | ≥3.5 | ≥4.3 | ≥5.3 | ≥6.2 | ≥7.0 |

Vertical and Horizontal Grip Strength, kN | ≥0.3 | ≥0.6 | ≥0.9 | ≥1.3 | ≥1.7 | ≥2.0 | ≥2.4 | ≥3.0 |

Thicknesses, mm | ≥1.2 | ≥1.6 | ≥1.8 | ≥2.4 | ≥2.8 | ≥3.0 | ≥3.2 | ≥3.4 |

Equivalent Pore Size, ο95 mm | 0.07~0.20 | |||||||

Vertical Permeability Coefficient,cm/s | ≤2.0×10-1 | |||||||

UV Strength Retention Rate | ≥80% | |||||||

Mass Per Unit Area,g/m2 | ≥100 | ≥150 | ≥200 | ≥300 | ≥400 | ≥500 | ≥600 | ≥800 |

Quality Deviation Per Unit Area | ±5% | ±4% | ±3% | |||||

Width Deviation | ±0.5% | |||||||

Tensile Strength of Geobags At Seams,kN/m | — | ≥6.5 | ≥9.0 | ≥16.0 | — | — | — | — |

Product Benefits

1. Lightweight: polypropylene resin as the main raw material, specific gravity of only 0.9, only three-fifths of cotton, with fluffy, good feel.

2. Soft: composed of fine fibers (2-3D) light point-like hot melt bonding molding. The finished product is moderately soft, with a sense of comfort.

3. Water-repellent, breathable: polypropylene slices do not absorb water, water content of zero, the finished water-repellent good, composed of 100% fiber with porous, breathable, easy to keep the cloth dry, easy to wash.

4. Non-toxic, non-irritant: the product is produced with FDA food-grade raw materials, does not contain other chemical components, stable performance, non-toxic, no odor, does not irritate the skin.

5. Antibacterial, anti-chemicals: polypropylene is a chemical blunt substance, not insect, and can isolate the presence of bacteria and insects within the liquid erosion; antibacterial, alkali corrosion, the finished product does not affect the strength of erosion.

6. Antibacterial. Products with water pulling, not moldy, and can isolate the existence of bacteria and insects in the liquid erosion, not moldy.

7. Good physical properties. Spun by the polypropylene directly laid into a network of thermal bonding and become, the strength of the product is better than the general short-fiber products, the strength of non-directional, longitudinal and transverse strength is similar.