Backfiltration Geotextile

The Backfiltration Geotextile boasts excellent chemical stability and is widely used in sewage treatment, chemical reaction tanks, and landfills. It can withstand high and low temperatures, as well as asphalt, oil, and tar. It is resistant to corrosion from over 80 types of strong acids, alkalis, and salts. The Backfiltration Geotextile has outstanding aging resistance, UV protection, and decomposition resistance, making it suitable for outdoor use. The material's lifespan can last from 50 to 70 years, providing a robust material guarantee for environmental seepage prevention.

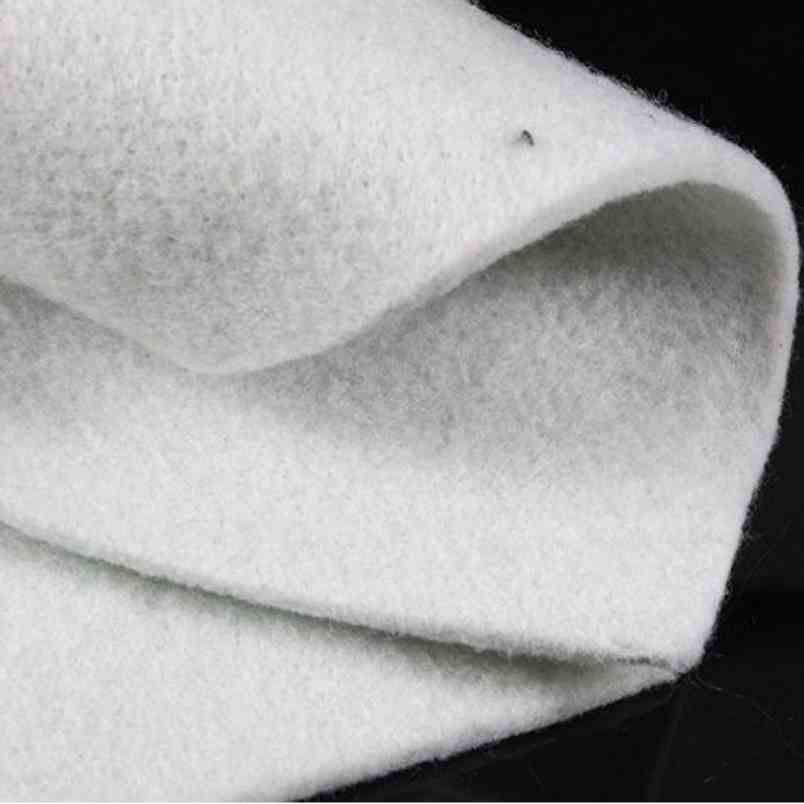

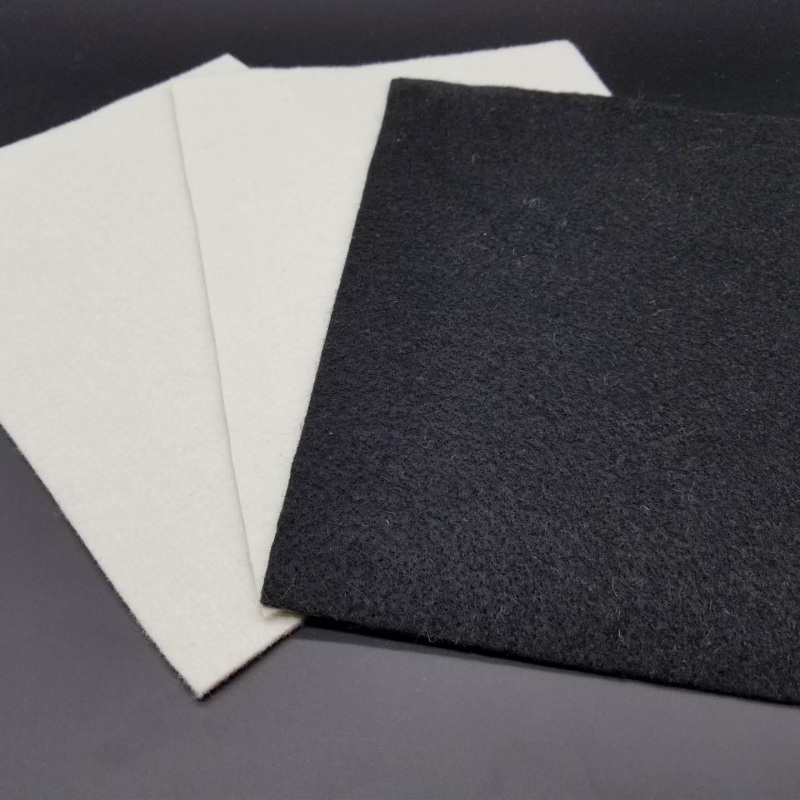

Product Presentation

Back filtration involves allowing liquid to pass through while preventing soil particles from being washed away by the permeation pressure. This process is called back filtration because it operates in the opposite direction of the water flow during filtration. Short filament needle-punched geotextiles can replace traditional gravel backfiltration layers, offering advantages such as reduced engineering work, easier construction, and faster installation. In water conservancy projects, they effectively prevent pipe seepage and leakage, thus preventing dam collapse. They are commonly used as a filter layer in roof gardens and garage top greening.

Product Features

The backfiltration geotextile has good mechanical strength and excellent elasticity and deformation ability, which makes it very suitable for the expansion or contraction of the foundation surface. It can effectively overcome the uneven settlement of the foundation surface. The tensile strength of fracture is 28MP and the elongation of fracture is 700%.

The new technology of the filter geotextile improves the seepage prevention effect, but the production process is more scientific and fast, and the product cost is lower than the traditional waterproof material. According to the actual calculation, the project using HDPE seepage prevention membrane can save about 50% of the cost.

The filter geotextile has high flexibility, and there are many specifications and laying forms to meet the requirements of different engineering seepage prevention. It is welded by hot welding, with high weld strength, convenient and fast construction.

The materials used in the backfiltration geotextile are all non-toxic and environmentally friendly materials. The principle of seepage prevention is ordinary physical change, which does not produce any harmful substances. It is the best choice for environmental protection, breeding and drinking water pool.