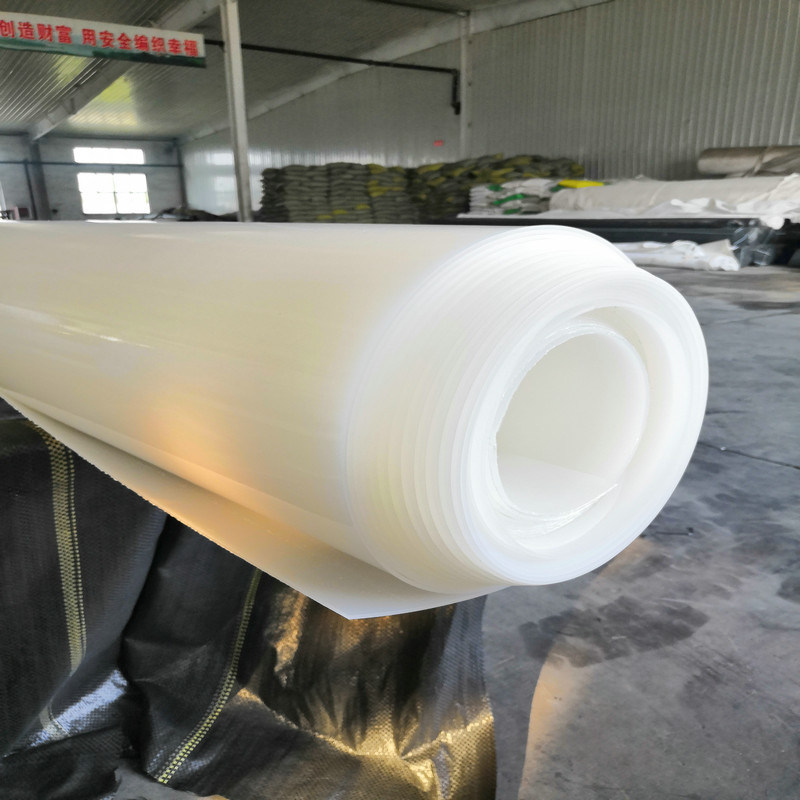

EVA Geomembrane

EVA geomembrane is mainly used in landfill plants, wastewater treatment plants and other waterproofing projects. EVA geomembrane is mainly used in tunnel composite lining, not suitable for exposed roofing. EVA geomembrane is mainly used in subway projects, tunnels, air raid shelters, water retaining dams, artificial lakes, industrial waterproofing and other projects. ECB is mainly used for waterproofing of subway, road, dam, tunnel and civil engineering.

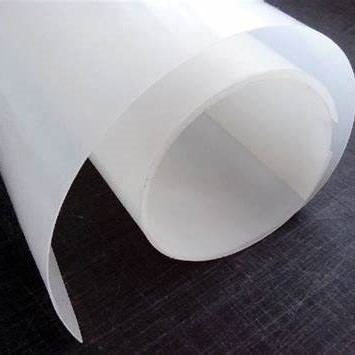

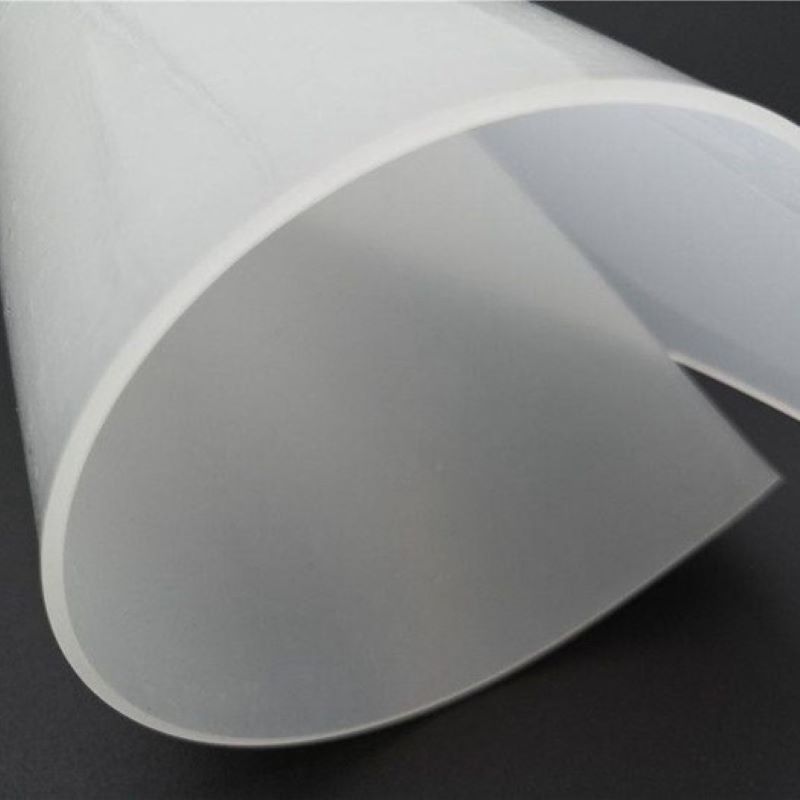

1. Complete width and thickness specifications (thickness 0.2-4mm; width 2.5-8m).

2. High flexibility and toughness.

3. High transparency.

4. Excellent resistance to environmental stress cracking.

5. Wide range of adaptable temperature.

6. Easy to lay and construct.

7. Suitable for subway, tunnel and other underground projects in complex terrain.

Product description

EVA geomembrane waterproof material is a multi-layer co-extruded film (seepage control membrane) and needle-punched geotextile using thermal composite technology composite geomembrane (a cloth a membrane, two cloth a membrane, two membranes and a cloth) the product has a high mechanical strength, aging resistance, puncture resistance, friction coefficient of the large, flexible, corrosion-resistant, etc., and both lightweight, wide, low-temperature resistance, waterproof, easy to lay and process, good weldability, etc. Advantages. Can be widely used in highways, airports, railroads, tunnels, water conservancy, dams, power plants, construction and other projects. It can play a role in reinforcement, isolation, anti-filtration, filtration, drainage, etc., and can extend the project life and reduce the cost of project maintenance. The use of the product construction is convenient, and easy to ensure the quality of the project. PE, EVA geomembrane is a new type of waterproof material, its material is soft, in the polyolefin class in the complementary flexibility and low-temperature resistance is optimal, is an alternative to PVC seepage control membrane. EVA geomembrane outstanding low-temperature flexibility is particularly suitable for the construction of cold areas. Our company can produce different VA content of EVA geomembrane according to the actual needs of users, so that EVA co-extruded impermeable membrane VA% content control in 5% -8% (the higher the VA content, the greater the elasticity, the lower the softening point) is a synthetic resin (HDPE, LDPE, EVA, ECB) as a substrate, adding antioxidants, ultraviolet absorbers, masterbatch and other auxiliaries and waterproof seepage control materials made. HDPE Geomembrane HDPE geomembrane, its physical and mechanical properties, aging resistance, chemical corrosion resistance, resistance to weathering of the environment, resistance to poking and prodding and other comprehensive features. LDPE, EVA elongation, good low temperature performance, soft and easy to construct. ECB geomembrane is made of ethylene copolymer mixed with petroleum resin, which is a higher grade of geomembrane.

Performance parameters

serial number | Indicato | Test Value | ||||

0.75mm | 1.00mm | 1.50mm | 2.00mm | 3.00mm | ||

1 | Minimum density,g/cm3 | 0.939 | ||||

2 | Tensile properties | |||||

Yield strength (stress),N/mm | 11 | 15 | 22 | 29 | 44 | |

Rupture strength (stress),N/mm | 20 | 27 | 40 | 53 | 80 | |

Yield elongation, % | 12 | |||||

Elongation at break, % | 700 | |||||

3 | Tear strength at right angles, N | 93 | 125 | 187 | 249 | 374 |

4 | Puncture strength, N | 240 | 320 | 480 | 640 | 960 |

5 | Resistance to environmental stress cracking (single point incision constant load tensile method), hr |

300 | ||||

6 | Carbon black | |||||

Carbon black content (range),% | 2.0-3.0 | |||||

Carbon black dispersion | 9 out of 10 observations should be class 1 or class 2, and no more than 1 should be class 3. | |||||

7 | Oxidation Induction Time (OIT) | |||||

Standard OIT,min, | 100 | |||||

High pressure OIT,min | 400 | |||||

8 | 85. C oven aging (min average) | |||||

Retention % of standard OIT after 90 d of baking | 55 | |||||

Retention % of high pressure OIT after 90d of baking | 80 | |||||

9 | UV resistance | |||||

After UV irradiation 1600hr, standard; % retention of OIT; | 50 | |||||

Retention % of high pressure OIT after UV irradiation 1600hr; | 50 | |||||

10 | -70℃low-temperature impact embrittlement performance | Passing | ||||

11 | Water vapor permeability parameter,g·cm(cm2· s ·Pa) | ≤1.0*10-13 | ||||

12 | Dimensional stability % | ±2 | ||||