Composite Geomembrane

Composite geomembrane is a high-performance engineering material designed for robust seepage control and environmental protection. It combines superior impermeability with exceptional resistance to aging, chemicals, and ultraviolet radiation, effectively blocking the migration of liquids, gases, and contaminants. With high tensile strength, puncture resistance, and deformation adaptability, it enhances soil stability and bearing capacity under various loads. Made from environmentally friendly polymer materials, it supports sustainable construction practices. Its flexibility allows for easy cutting, welding, and installation, significantly reducing project time and cost. Ideal for landfills, water conservancy, mining, and aquaculture applications, it ensures long-term project durability and reliable protection of soil and water resources.

Product description

Composite Geomembrane, widely used in channel seepage control project. In recent years, geosynthetics in civil engineering, especially in the flood control and rescue projects in a large number of applications and their effectiveness, caused the majority of engineers and technicians attach great importance to. For the application of geosynthetics technology, the state from the seepage control, anti-filtration, drainage, reinforcement, protection, etc., put forward a standardized technical requirements, greatly accelerating the pace of the promotion and application of new materials. The material is widely used in the irrigation channel seepage control project, combined with construction practice, the composite geomembrane application technology.

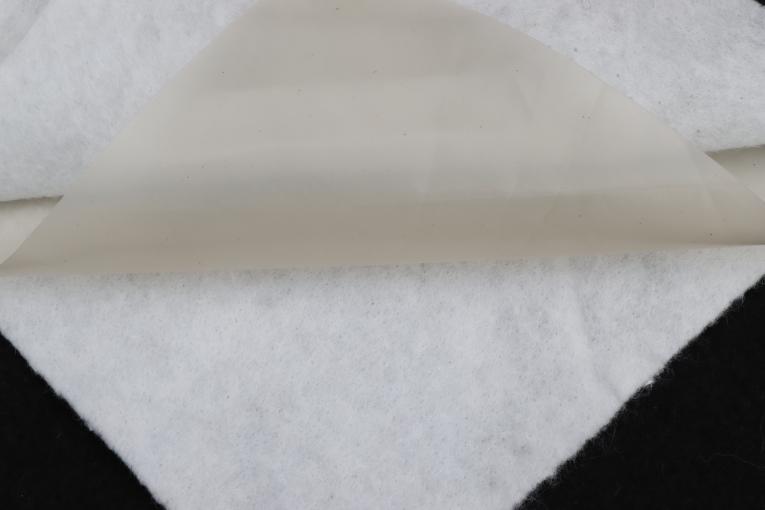

Composite Geomembrane is a geotextile and geomembrane composite impermeable materials, it is mainly used for seepage control, composite geomembrane is divided into a cloth a membrane and two cloth a membrane, width 4-6m, weight 200-1500g/m2, tensile, tear resistance, top broken and other physical and mechanical properties of the index is high, to meet the water conservancy, municipal, construction, transportation, subway, tunnels and other civil engineering needs. Because of its selection of polymer materials and production process added anti-aging agent, so it can be used in non-conventional temperature environment.

Composite Geomembrane (composite seepage control membrane) is divided into a cloth and a membrane and two cloth and a membrane, the width of 4-6m, the weight of 200-geomembrane production workshop 1500g / square meter, tensile, tear resistance, top broken and other physical and mechanical properties of the index is high, the product has a high strength, good elongation, deformation modulus, acid and alkali, corrosion, aging, seepage control performance is good, etc. Features. Can meet the water conservancy, municipal, construction, transportation, subway, tunnel, engineering construction of seepage control, isolation, reinforcement, anti-cracking reinforcement and other civil engineering needs. Commonly used in embankment dams, drainage ditches seepage control treatment, as well as anti-pollution treatment of waste sites.

Composite geomembrane is in one or both sides of the film through the oven far-infrared heating, the geotextile and geomembrane by the guide roller pressed together to form a composite geomembrane. With the improvement of the production process, there is also a casting method to do the composite geomembrane process. Its form has one cloth and one membrane, two cloths and one membrane, two membranes and one cloth. Geotextile as a protective layer of geomembrane, so as to protect the impermeable layer from damage. In order to reduce ultraviolet irradiation and increase anti-aging properties, it is best to use the buried method of laying. In construction, first of all, the material diameter of small sand or clay to level the base surface, and then lay the geomembrane. Geomembrane do not taut, both ends buried in the soil part of the corrugated, and finally in the geomembrane paved with fine sand or clay paved a layer of 10cm or so transition layer. Lay 20-30cm stones (or concrete prefabricated blocks) as a protective layer against washout. During the construction, every effort should be made to avoid the stone directly hit on the geomembrane, and it is better to carry out the construction of the protective layer while paving the membrane. Composite geomembrane and the surrounding structures should be connected by expansion bolts and steel plate pressure strip anchorage, the connection part should be coated with emulsified asphalt (2mm thick) bonding to prevent leakage at the place.

Product parameter

| serial number | indicators | Test Value | ||||||||||

1 | Mass per unit area g/㎡ | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | ||||

2 | Membrane thickness mm | 0.25-0.35 | 0.30-0.50 | |||||||||

3 | physical property | |||||||||||

Rupture strength KN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | |||||

Elongation at break % | 30-100 | |||||||||||

CBR Top Break Strength KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | |||||

Tear strength KN | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | |||||

Peel strength N/cm | ≥6 | |||||||||||

4 | Hydrostatic pressure resistance | |||||||||||

Membrane thickness mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | |||||

One Fabric One Membrane Mpa | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | |||||

Two cloth one membrane Mpa | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |||||