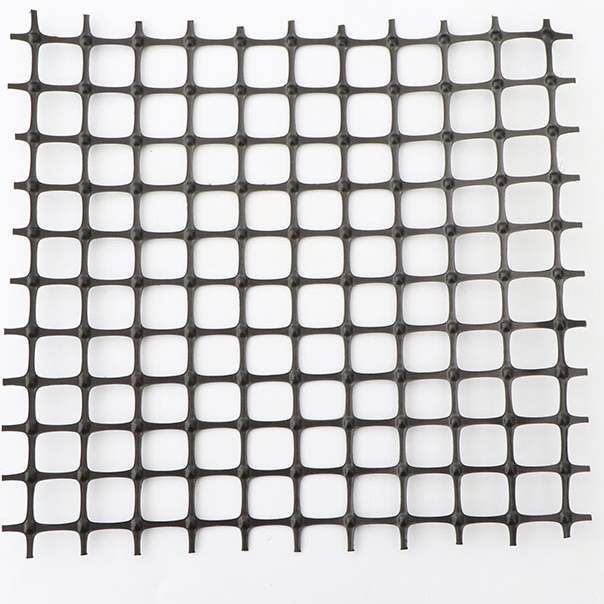

Mining Plastic Grids

Mining Plastic Grids are made of high-quality HDPE/PP materials with a tensile strength of 50-200kN/m, which can effectively disperse the pressure of the ore layer. They have excellent acid and alkali resistance (pH2-12) and UV resistance, and their underground service life exceeds 20 years. The unique three-dimensional grid structure (porosity > 90%) achieves efficient two-way drainage and prevents water pressure accumulation.

Mining Plastic Grids are manufactured from high-grade HDPE/PP polymers through advanced extrusion and punching technology. The three-dimensional grid structure features a porosity exceeding 90%, creating an optimal balance between strength (50-200kN/m tensile strength) and drainage capacity. This unique design makes Mining Plastic Grids particularly suitable for underground mining applications where both load distribution and water management are critical requirements.

The Mining Plastic Grids demonstrate exceptional technical characteristics:

- Mechanical Strength: Withstands mining pressures up to 200kN/m while maintaining structural integrity

- Chemical Resistance: Stable performance in pH 2-12 environments, resisting acid mine drainage

- Durability: UV-stabilized formulation ensures 20+ years service life in harsh mining conditions

- Hydraulic Efficiency: Bidirectional drainage capacity prevents water pressure buildup behind support structures

Mining-specific Applications

Mining Plastic Grids provide comprehensive solutions for:

- Roof support systems in underground mines

- Reinforcement of tailings dam slopes

- Stabilization of mining haul roads

- Foundation improvement for heavy equipment areas

The combination of high strength, excellent drainage properties, and long-term durability makes Mining Plastic Grids the ideal choice for modern mining engineering projects.